Engineered and Manufactured In-House.

Dexterous Mold & Tool was established as C&E Mold in 1979. After outgrowing its original location, the company was relocated to their present location in 1992 and a new name was chosen. From its early days in a small pole barn, Dexterous has now grown into a 22,500 sq ft, state of the art manufacturing facility. Now managed by the 2nd generation of family members, we hope to have continued growth and success for our customers and very dedicated employees.

Dexterous Mold & Tool focuses on the auto, medical, consumer goods and packaging industries. We specialize in complicated mold actions of cams, lifts and auto unscrewing. We have been ISO Certified since 2000. All our work is engineered and manufactured in house. Our skilled professionals have the experience to provide ideas and recommendations that satisfy your prototype and production tooling needs. Dexterous Mold & Tool always strives to produce the best quality tools to fit our customers’ timeline.

Skilled & Experienced Mold Designers

Our design engineers boast a combined 30+ years of mold design experience. All our molds are designed in 3-D using Creo (Pro-Engineer) and SolidWorks. We stay up to date on our engineering software and hardware to offer our customers the best designs possible. From initial part concept to full mold design, our skilled mold designers and management will work with you every step of the way to design molds of unsurpassed quality, accuracy and durability.

Professional Journeymen & Machinists

Dexterous Mold and Tool is staffed with professional journeymen and skilled machinists. Our CNC machinists program with the latest Mastercam software to produce high quality parts. Our journeymen have the skills and experience necessary to build new tools and to repair old ones. The employees at Dexterous will produce high quality work with prompt delivery.

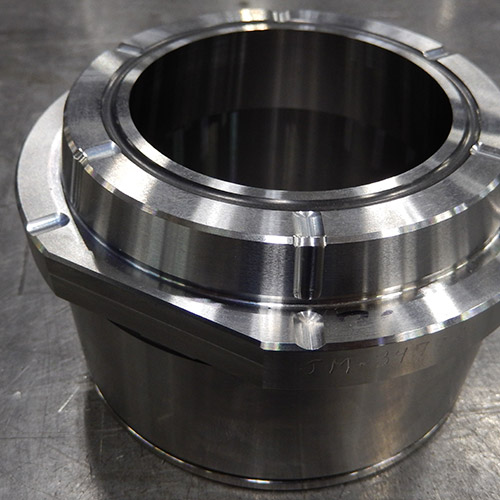

Quality Machining of Complex Surfaces.

Our 5-axis CNC machining centers, 3-axis CNC machining centers, CNC lathe and Mill-Turn Center allow Dexterous Mold to machine complex surfaces on all types of parts.

Our CNC wire EDM machines are programmed using the latest wire EDM software. We have the capability to create complex shapes while holding tight tolerances.

Our high-speed graphite mills and CNC die-sinking EDM machines allow for high quality EDM work. A tool changing robot makes use of two 150 position tool changers and a palletizing system to save time and money.

Dexterous Mold is staffed with two highly skilled polishers. This allows us to save time and have better control over our finished part surfaces.

Dexterous Mold has two laser welders. Whether you need an emergency repair, an engineering change or just a little reconditioning, our laser welders can weld it.